| Product module | MMS6120 |

| Brands | EMERSON |

| Payment | Paypal/TT |

| Condition | 100%New |

| Weight | 0.3KG |

| Production year | 2024 |

| Contry origin | USA |

Decription

| Part number :MMS6120 |

| Versorgungsspannung: 18....24....31.2 V DC entsprechend IEC 654-2, Klasse DC4 |

| Leistungsaufnahme: max. 6 W (max. 250 mA bei 24 V) |

| Frequenzbereich: 0,1 Hz..5kHz(± 20 %/-3 dB) |

| Lastwiderstand: 210 KΩ |

| Auflösung:16Bit |

|

Genauigkeit::±1 % des MeBbereichs |

| Dimensions:3x19x12.7cm |

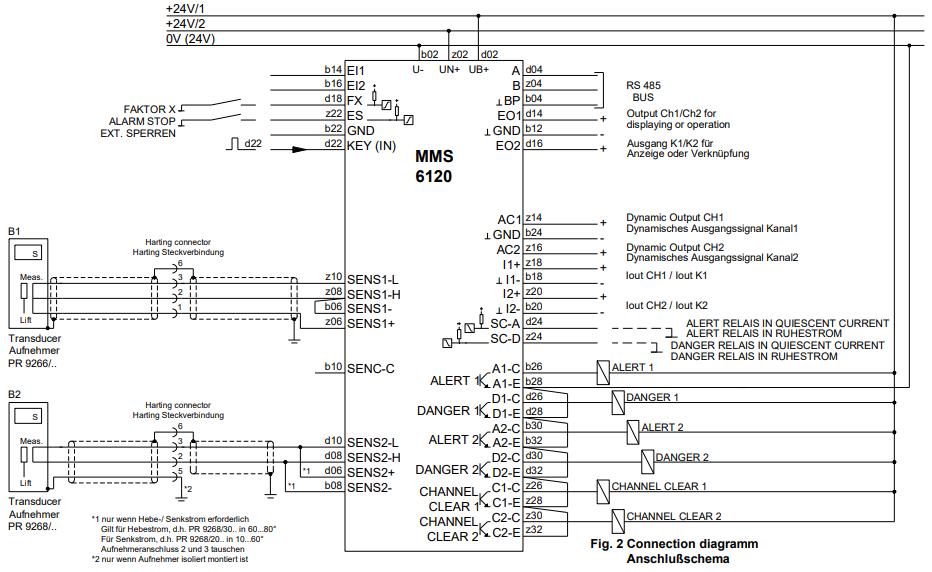

The MMS6120 Dual Channel Bearing Vibration Monitor is a sophisticated monitoring device designed to

assess the condition of rotating machinery. This device provides real-time data on vibration levels, enabling

users to detect potential issues before they escalate into significant problems. With its dual-channel capability,

the MMS6120 can simultaneously monitor multiple points on a machine, offering a comprehensive view of its

operational health. Its advanced algorithms analyze vibration patterns, helping to identify abnormal conditions such as

misalignment, imbalance, or bearing wear. Additionally, the user-friendly interface facilitates easy setup and configuration,

making it accessible for operators at all levels. Overall, the MMS6120 plays a crucial role in

predictive maintenance, ultimately improving equipment reliability and extending service life.

Email: sales@amikon.cn

Freequently Asked Questions About MMS6120

| What is the primary function of the MMS6120 Dual Channel Bearing Vibration Monitor? |

|

The primary function of the MMS6120 is to monitor vibration levels in rotating machinery, enabling early detection of potential issues to prevent failures. |

| How does the dual-channel capability benefit monitoring? |

|

The dual-channel capability allows simultaneous monitoring of multiple points on a machine, providing a comprehensive view of its health and performance. |

| What types of machinery can the MMS6120 monitor? |

|

The MMS6120 can be used to monitor a variety of rotating machinery, including motors, pumps, fans, and compressors. |

| How is the MMS6120 set up and configured? |

|

Setup and configuration are user-friendly, involving connecting the monitor to the machinery and using the interface to select monitoring parameters. |

Recommended model

| EMERSON | R6423/010-010 CON021 | Eddy Current Sensor |

| EMERSON | PR6423/00R-111-CN CON041 | Eddy Current Sensor |

| EMERSON | KJ3201X1-BA1 12P2535X052 | Isolated Card |

| EMERSON | KJ2201X1-JA1 12P3323X022 | Terminal Block |

| EMERSON | KJ2201X1-BA1 12P3162X162 VS3202 | Logic Solver |

| EMERSON | KJ3202X1-BA1 12P2536X042 VE4032S1T2B1 | DeltaV Discrete Output Card |

| EMERSON | KJ4001X1-JA1 12P1832X022 | Terminal Block |

| EMERSON | KJ3002X1-BC1 12P0681X072 VE4003S1B2 | Analog Input |

| EMERSON | KJ3002X1-BC1 12P0681X082 VE4003S1B2 | Analog Input Module |

| EMERSON | KJ3002X1-BC1 12P0681X092 VE4003S1B2 | PLC Module |

| EMERSON | PR6424/006-111 CON031 | Eddy Current Sensor |

| EMERSON | KJ3007X1-EA1 12P2413X032 | PROFIBUS TERMINAL BLOCK |

If you want to more,please contact me without hesitate.

Email: sales@amikon.cn

Inventory Products

More than 40.000.000 products available and worldwide support